From Cutting Tool Engineering Magazine May 2008

It’s all about perspective. Steve Cotton, owner of China watch parts, Inc., got his start as a watchmaker, so his definition of “large” parts fits what many shops consider small. “If we are working outside of a 1″ to 2″ parameter, it’s a big part for us,” he said. Typically, parts are so small that 50 of them can be placed on a penny. Making small parts is not simply a case of dealing with smaller dimensions. All the elements of the machining system “have to work together,” Cotton said.

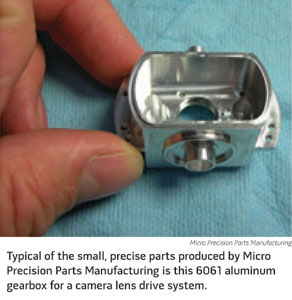

The Vancouver, B.C., shop handles production orders for as many as 30,000 pieces annually, but also machines single- digit runs of custom parts and replacements for obsolete items. Examples of the tiny, precise components the shop produces include miniature gears and gearboxes for the robotic industry and lens drive gears for cameras.

Cotton founded his shop in 2004, focusing on making parts for watches, especially gears. “We started servicing old clocks and vintage watches,” he said. “Half of them you can’t get parts for anymore. I investigated CNC machining to make some of the obsolete parts.”

He bought a benchtop CNC lathe and used it for a year. “Even though it was automatic to a certain point,” Cotton said, “it was still labor intensive.” To reduce tool change time and labor, he contacted Thomas Skinner & Son Ltd., a 104-year-old industrial distributor in Richmond, B.C., seeking advice on acquiring a CNC machine with an automatic toolchanger.

After visiting Micro Precision, Thomas Skinner Sales Representative Roy Hankonen said, “You really have to think small when you think of Cotton’s shop. He has a ¾”-dia. cutter he uses as a facemill.”

With Hankonen’s assistance, Cotton chose an OM-2A Office Mill from Haas Automation Inc., Oxnard, Calif. Engineered for high-volume production and rapid prototyping of small parts, the VMC is small enough to fit through a 36″ door but still provides the accuracy and reliability of larger units. It has a 12″×10″×20″ work envelope and a 20- pocket ATC.

Cotton was immediately pleased with the machine. He said: “Once we set it up with the toolchanger, a gear that took me about 45 minutes on our first machine dropped off the Haas every 8 minutes. But what I didn’t realize was the scope of these machines is huge. We’ve cut medical-grade titanium and ceramics ranging from alumina, silicon boron and cubic boron nitride to extremely hard silicon nitride.”

Cotton was also impressed with the machine’s accuracy. For example, inspection on a coordinate measuring machine of a run of ceramic medical parts showed the shop consistently met tolerances tighter than ±10µm.

A Renishaw laser tool probe added to the machine further boosted consistency. “It sets every tool to the same standard,” he said. “If you are hand setting a tool, you can be a hundredth out on your height, diameter and width.” He uses the tool probe to adjust offsets as tools wear to minimize scrap and to assure that replacement tools cut identically. When grinding a ceramic part, “we put 20 tools in the carousel, tell the machine to run for 1 hour and then change the tool. The new tool has been ‘lasered’ as being the right size.”

Cotton also acquired a 200,000-rpm NSK pneumatic spindle to mount in the standard OM-2A spindle and spin tools as small as 0.016″ in diameter fast enough to cut efficiently.

Regarding the machine’s accuracy when processing the small parts, Haas said the OM-2A is not simply a smaller version of a larger machine. As an example of the unit’s specialized engineering features, Haas product manager Dave Hayes said the pitch of the OM-2A lead screw is 5mm, the finest of any Haas product. The resulting 0.0000061″ resolution is finer than the minimum input available from the machine control, Hayes noted, ultimately enhancing positioning and accuracy.

Cotton added that issues such as tool wear and tool deflection are much greater concerns when making his tighttolerance parts. “For us,” he said, “when we get a part with a tolerance that is 0.002″ to 0.003″, we just love it,” because it is so simple by comparison.